-

- Turbulence is one of the most frequent causes of injuries on airplanes, every year in the United States some 65,000 aircraft suffer moderate turbulence and 5,500 run into severe turbulence, costing the US airlines up to $500 million per year, due to injuries, delays and damages.

- It is time to develop solutions that mitigate the risk of injury due to turbulence, perhaps a bicycle style helmet for flight attendants?

- This article reports that Singapore Airlines flight SQ321 on 21 May 2024 was not hit by clear air turbulence, but rapidly developing thunderstorms.

Most of us have experienced turbulence while traveling: when your plane flies through clashing bodies of air moving at widely different speeds.

Severe turbulence can put even the most seasoned flier on edge and make five minutes seem like an eternity. Usually it results in nothing more than a bumpy ride, but in the worst cases it can cause damage, injury and – in the case of Singapore Airlines flight SQ321 on May 21 – fatality.

In nonfatal accidents, turbulence is the leading cause of injuries to flight attendants and passengers, according to the Federal Aviation Administration, and it’s one of the most common airline accident types today, according to the US National Transportation Safety Board. It costs US airlines – due to injuries, delays and damages – up to $500 million per year, according to the National Center for Atmospheric Research.

“There is a scale for measuring how strong turbulence is,” Paul Williams, a professor of atmospheric science at the University of Reading in the UK, told CNN in 2022. “There’s light turbulence, which is a bit of strain against your seat belt, but food service can continue and you can probably walk around the cabin, maybe with some difficulty.

“Then there’s moderate turbulence, a definite strain against seat belts, anything that’s not secured will be dislodged, and walking is difficult; flight attendants are usually instructed to take their seats.

“The worst kind is severe turbulence: This is stronger than gravity, so it can pin you to your seat and if you’re not wearing your seat belt you’ll be tossed around inside the cabin. This is the kind of turbulence that causes serious Injuries – it’s been known to break bones, for example.”

Strikes fast and no visual clues

About 65,000 aircraft suffer moderate turbulence every year in the US, and about 5,500 run into severe turbulence. These numbers, however, might be destined to grow. Williams believes that climate change is modifying turbulence, and started studying the subject in 2013. “We ran some computer simulations and found that severe turbulence could double or triple in the coming decades,” he says.

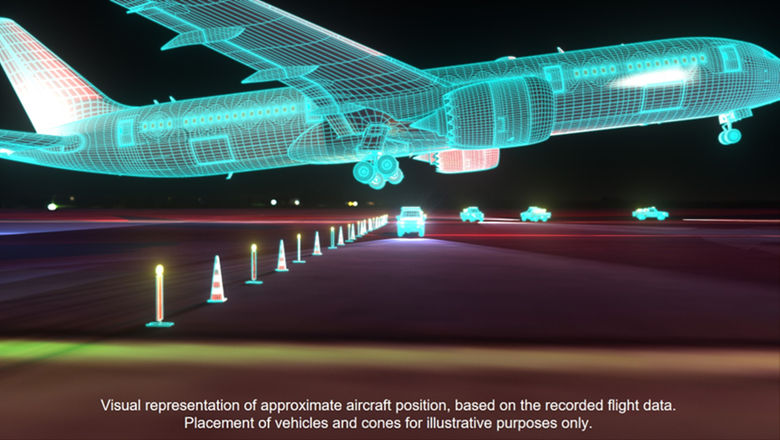

The findings, which were later confirmed by observations, highlight a type of turbulence called “clear air turbulence,” which isn’t connected to any visual clues such as storms or clouds. Unlike regular turbulence, it hits suddenly and is hard to avoid. The Singapore Airlines flight of May 21 was not hit by clear air turbulence, but rapidly developing thunderstorms.

According to the NTSB, between 2009 and 2018, the flight crew had no warning in about 28% of turbulence-related accidents. Williams’ analysis predicts that clear-air turbulence will increase significantly around the globe by the period 2050-2080, in particular along the busiest flight routes, and the strongest type of turbulence will increase the most.

That doesn’t mean, however, that flying will be less safe. “Planes are not going to start falling out of the sky, because aircraft are built to very high specification and they can withstand the worst turbulence they can ever expect to encounter, even in the future,” says Williams.

However, the average duration of turbulence will increase. “Typically, on a transatlantic flight, you might expect 10 minutes of turbulence. I think that in a few decades this may increase to 20 minutes or to half an hour. The seat belt sign will be switched on a lot more, unfortunately for passengers.”

Keeping your seat belt fastened at all times while seated is the best way to minimize the risk of injury due to turbulence.

Flight attendants, however, are more exposed to that risk than passengers and sustain approximately 80% of all turbulence-related injuries. “We’re the most likely to get hurt because we’re up working, pushing 300-pound carts, even when there’s some sort of warning,” Sara Nelson, a United flight attendant with more than two decades of experience and the president of the Association of Flight Attendants, a union representing 50,000 flight attendants across 20 airlines, told CNN in 2022.

“We have flight attendants who have been thrown into the ceiling and then back down several times, resulting in broken limbs. In the aisle, with unannounced turbulence, we had people who lost toes, or lost the ability to work, or sustained injuries that kept them off the job for years,” she adds.

The aviation industry is taking the problem very seriously, Nelson says, but the transition to sustainable fuel must accelerate to tackle the climate crisis, and some regulations need to change. For example, the ability for children under the age of two to fly on their parents’ lap.

“That is totally unsafe and our union has been calling for a seat for every person on board,” Nelson says. “Not only can a child be thrown around the cabin, but when they come down they can actually hurt someone else, too. When a child is born, you can’t leave the hospital unless you have a properly installed car seat. The same standards must be applied to flying.”

Calls for stringent new rules

The NTSB held a public meeting about turbulence in 2021, during which it offered the same recommendation, along with more stringent rules about fastening seat belts for both passengers and flight attendants when the aircraft is flying in the vicinity of thunderstorms and under 20,000 feet, as most injuries occur under these conditions. It also recommended to streamline the systems for collecting and sharing turbulence reports, because that information isn’t traveling widely or promptly enough at the moment.

While the effects of climate change on turbulence will take many years to become obvious, Nelson believes some worsening has already occurred.

“This is of course anecdotal, but from Hurricane Katrina forward there seems to have been a pickup in the activity of turbulence, especially turbulence that comes with no warning,” she says.

Her worst ever turbulence experience occurred during a flight to Dallas, which was eventually diverted.

“When anything happens on the plane, the passengers look to us, to see if we look concerned,” she adds. “I was flying with a very good friend of mine and we were strapped in on the jump seats, facing the back of the aircraft – so there was a lavatory in front of us, instead of passengers.

“Thank goodness, because we were clutching each other and we were getting thrown around in our seats so violently that it felt like our brains were getting scrambled. It went on for a very long time, but luckily we got safely on the ground,” she says.

“Typically I’m not scared of turbulence, because it’s something that we’re taught about in training and we know what to do to protect ourselves. But it is possible to have turbulence so bad and go on for so long that even knowing all of that, my friend and I were praying – and I have to say I was scared for my life.”

This story was originally published in September 2022. It was updated and republished in May 2024 by CNN.